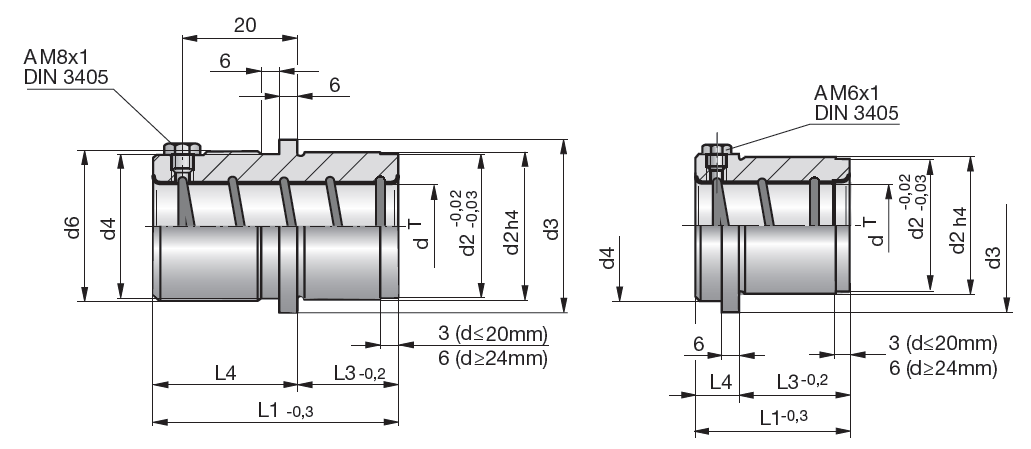

Guide bush Z4411

Description

Ask For Quote| Product name | Guide bush Z4411 |

| Standard | DIN9831-1/ISO 9448 |

| Manufacturer | MQ Mold |

| Place of origin | Ningbo, China |

| Material | Steel + CuSn12 |

| Hardness | HRC 52±2 |

| Mode | Factory & trade |

| d | L1 | T | d2 | d3 | d4 | d5 | d6 | L3 | L4 |

| 19/20 | 32 | A/B/C | 32 | 40 | 32 | 49 | - | 20 | 12 |

| 50 | A/B/C | 32 | 40 | 32 | 49 | 34 | 20 | 30 | |

| 70 | A/B/C | 32 | 40 | 32 | 49 | 34 | 20 | 50 | |

| 24/25 | 35 | A/B/C | 40 | 48 | 40 | 57 | - | 23 | 12 |

| 60 | A/B/C | 40 | 48 | 40 | 57 | 42 | 23 | 37 | |

| 80 | A/B/C | 40 | 48 | 40 | 57 | 42 | 23 | 57 | |

| 30/32 | 42 | A/B/C | 48 | 56 | 48 | 65 | - | 30 | 12 |

| 75 | A/B/C | 48 | 56 | 48 | 65 | 50 | 30 | 45 | |

| 95 | A/B/C | 48 | 56 | 48 | 65 | 50 | 30 | 65 | |

| 38/40 | 50 | A/B/C | 58 | 66 | 58 | 75 | - | 35 | 15 |

| 80 | A/B/C | 58 | 66 | 58 | 75 | 60 | 35 | 45 | |

| 110 | A/B/C | 58 | 66 | 58 | 75 | 60 | 35 | 75 | |

| 48/65 | 65 | A/B/C | 70 | 80 | 70 | 89 | - | 45 | 20 |

| 90 | A/B/C | 70 | 80 | 70 | 89 | 74 | 45 | 45 | |

| 120 | A/B/C | 70 | 80 | 70 | 89 | 74 | 45 | 75 | |

| 60/63 | 75 | A/B/C | 85 | 95 | 85 | 104 | - | 55 | 20 |

| 100 | A/B/C | 85 | 95 | 85 | 104 | 89 | 55 | 45 | |

| 130 | A/B/C | 85 | 95 | 85 | 104 | 89 | 55 | 75 | |

| 80 | 85 | A/B/C | 105 | 118 | 105 | 127 | - | 55 | 30 |

| 120 | A/B/C | 105 | 118 | 105 | 127 | 112 | 55 | 65 | |

| 150 | A/B/C | 105 | 118 | 105 | 127 | 112 | 55 | 95 |

| Die clearance | ||||

| small | Workpieces with close tolerances and certain properties of the cut contours; also thin materials. | Class 1 | ||

| medium | Workpieces made of sheet metal thickness more than 1mm, preferably for follow-on composite tools. | Class 2 | ||

| large | Less stringent requirements with regard to edge definition; cutting pressure and cutting work are distinctly lower when working with a large die clearance than when working with a small or medium die clearance. | Class 3 | ||

| Play | Guide pillar | Guide bushes |

| Class 1 | A | A |

| Class 2 | A | B |

| Class 3 | A | C |

| Guide pillar/μm | Total play/μm | Guide bushes/μm | |||||

| φ15/16 | -2~0 | A | 4~9 | 4~7 | A | φ15/16 | |

| 7~14 | 7~12 | B | |||||

| 12~19 | 12~17 | C | |||||

| φ19/20 | -3~0 | A | 4~11 | 4~8 | A | φ19/20 | |

| 9~16 | 9~13 | B | |||||

| 14~22 | 14~19 | C | |||||

| φ24/25 | -3~0 | A | 5~12 | 5~9 | A | φ24/25 | |

| 10~18 | 10~15 | B | |||||

| 16~25 | 16~22 | C | |||||

| φ30/32 | -3~0 | A | 5~12 | 5~9 | A | φ30/32 | |

| 10~19 | 10~16 | B | |||||

| 17~28 | 17~25 | C | |||||

| φ38/40 | -3~0 | A | 5~13 | 5~10 | A | φ38/40 | |

| 11~21 | 11~18 | B | |||||

| 19~32 | 19~29 | C | |||||

| φ48/50 | -3~0 | A | 6~14 | 6~11 | A | φ48/50 | |

| 12~23 | 12~20 | B | |||||

| 21~35 | 21~32 | C | |||||

| φ60/63 | -3~0 | A | 6~14 | 6~11 | A | φ60/63 | |

| 12~24 | 12~21 | B | |||||

| 22~36 | 22~33 | C | |||||

| φ80 | -3~0 | A | 7~13 | 7~10 | A | φ80 | |

| 13~23 | 13~20 | B | |||||

| 23~36 | 23~33 | C | |||||