Japanese standard latch locks

Description

Ask For QuoteSurface treatment: yellow plating

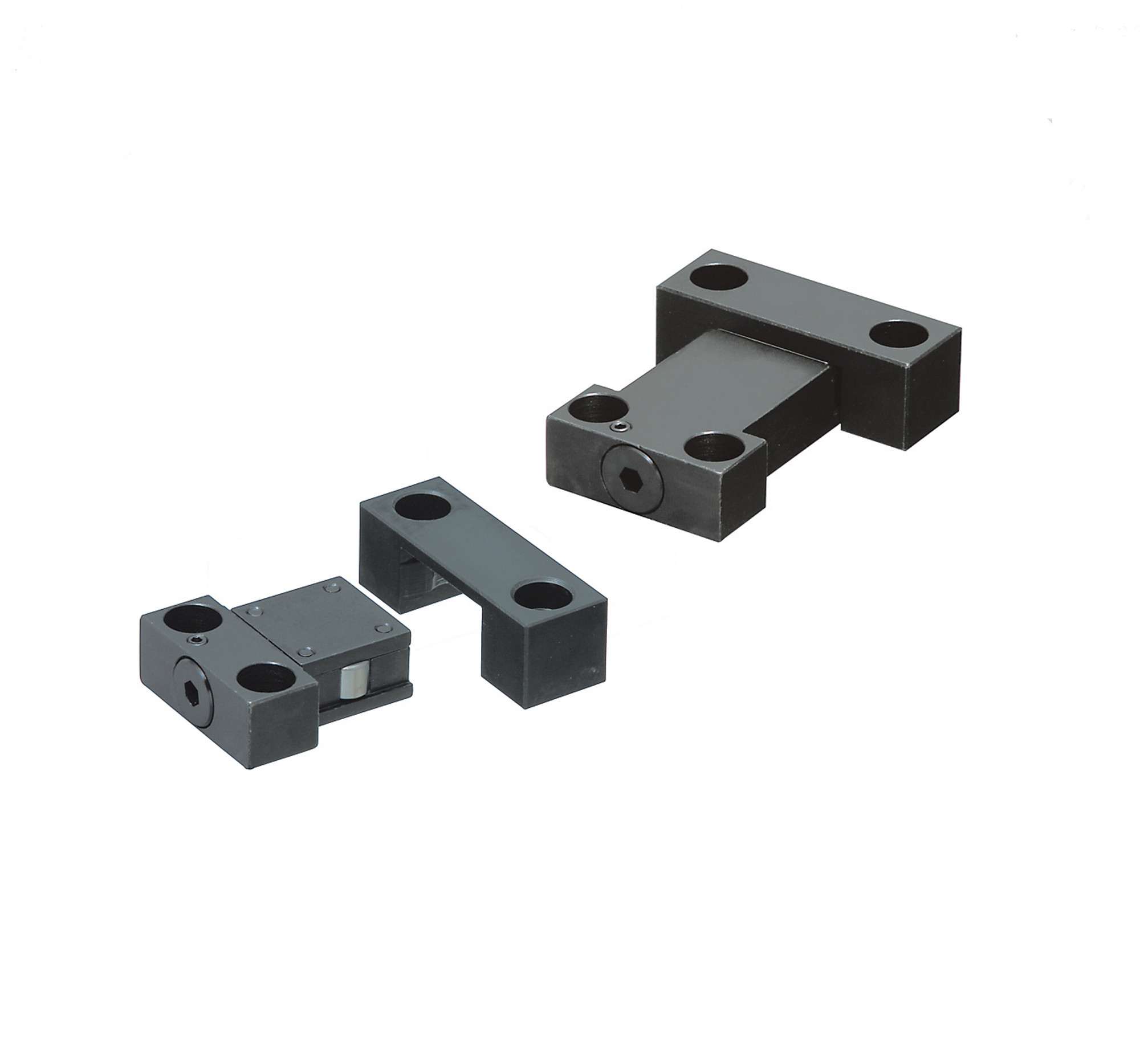

Assemble tips:

Adjust force of the locks by hexagon wrench. When tightening screws fully, it could reach max. loading.

For keeping balance well during motion, the locks need to be assembled symmetrically on the molds.

The locks should to be assemble paralleling to the parting surface.

Product name | Japanese Standard Latch locks |

Standard | Japanese standard |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | S50C |

Hardness | - |

Mode | Factory & trade |

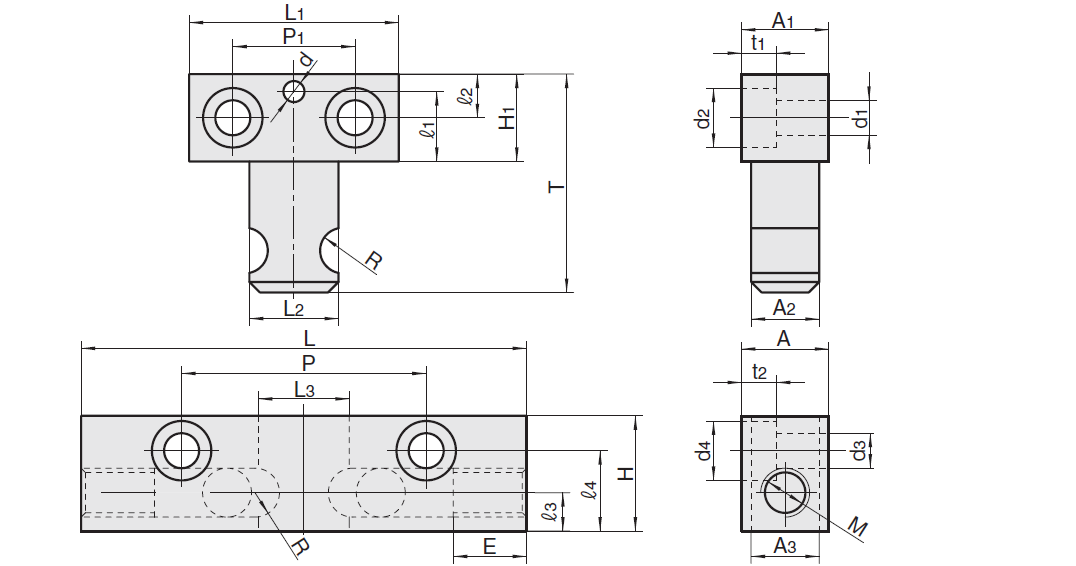

| Model No. | Max. loading | L1 | P1 | l1 | l2 | T | H1 | L2 | t1 | A1 | d | d2 | d1 | A2 | R | L | P | L3 | l3 | l4 | H | E | t2 | A | d4 | d3 | A3 | M | |

| Type | No. | ||||||||||||||||||||||||||||

| C-MPSLB | 300 | 2942N(300kg) | 40 | 25 | 14 | 12 | 48 | 20 | 17.5 | 6.5 | 20.5 | 5 | 10.5 | 6.5 | 12 | R4.25 | 88 | 60 | 18 | 10 | 21 | 28 | 20 | 6.5 | 20.5 | 11 | 6.5 | 12.5 | M12x1.7 |

| 500 | 4902N(500kg) | 60 | 35 | 20 | 12.5 | 62.5 | 25 | 25.5 | 10 | 30 | 6 | 17 | 10 | 19.5 | R6.5 | 127.5 | 70 | 26 | 11 | 23 | 33 | 21 | 10 | 30 | 17 | 10 | 20 | M14x2.0 | |