Roller lock sets

Description

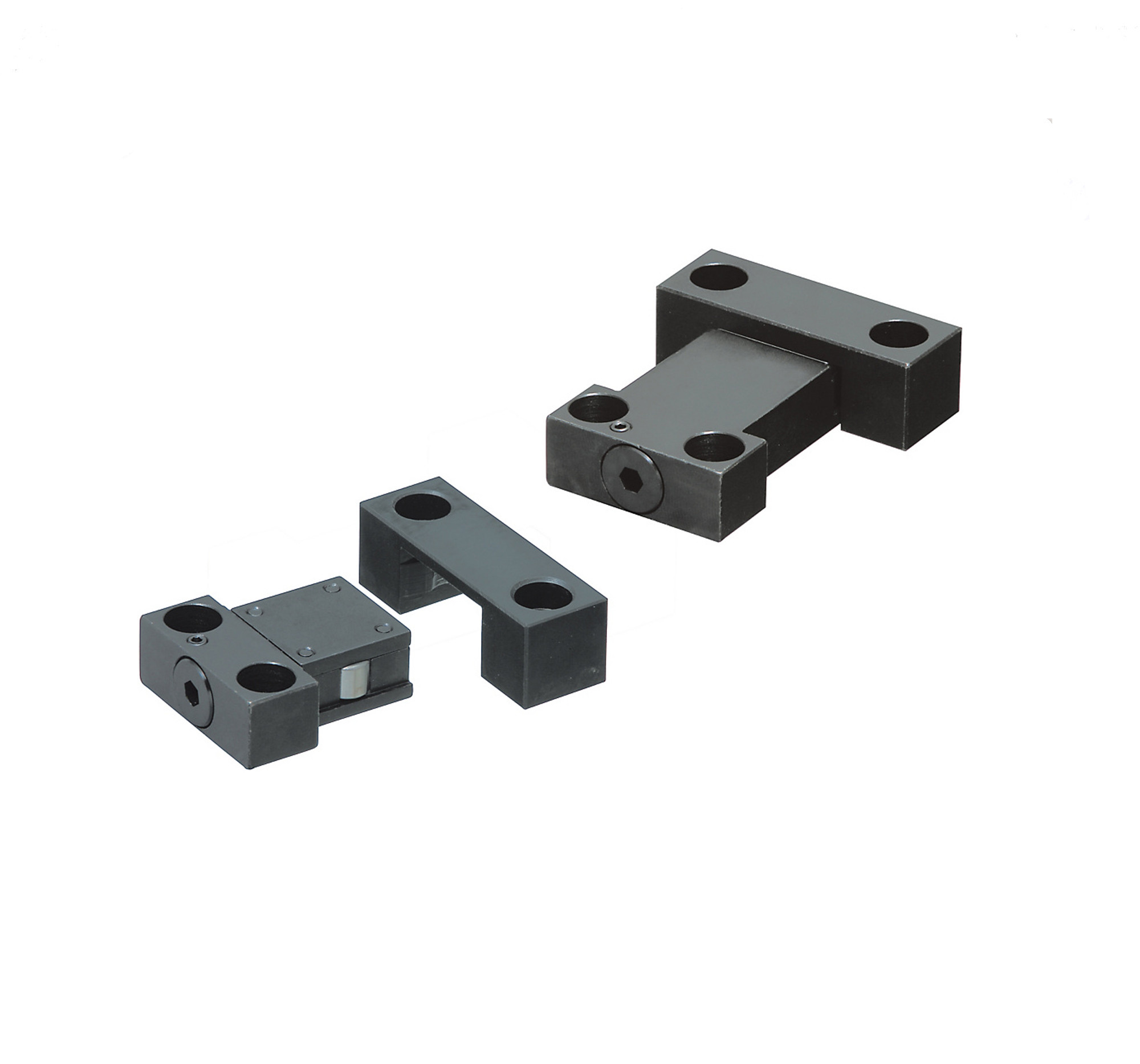

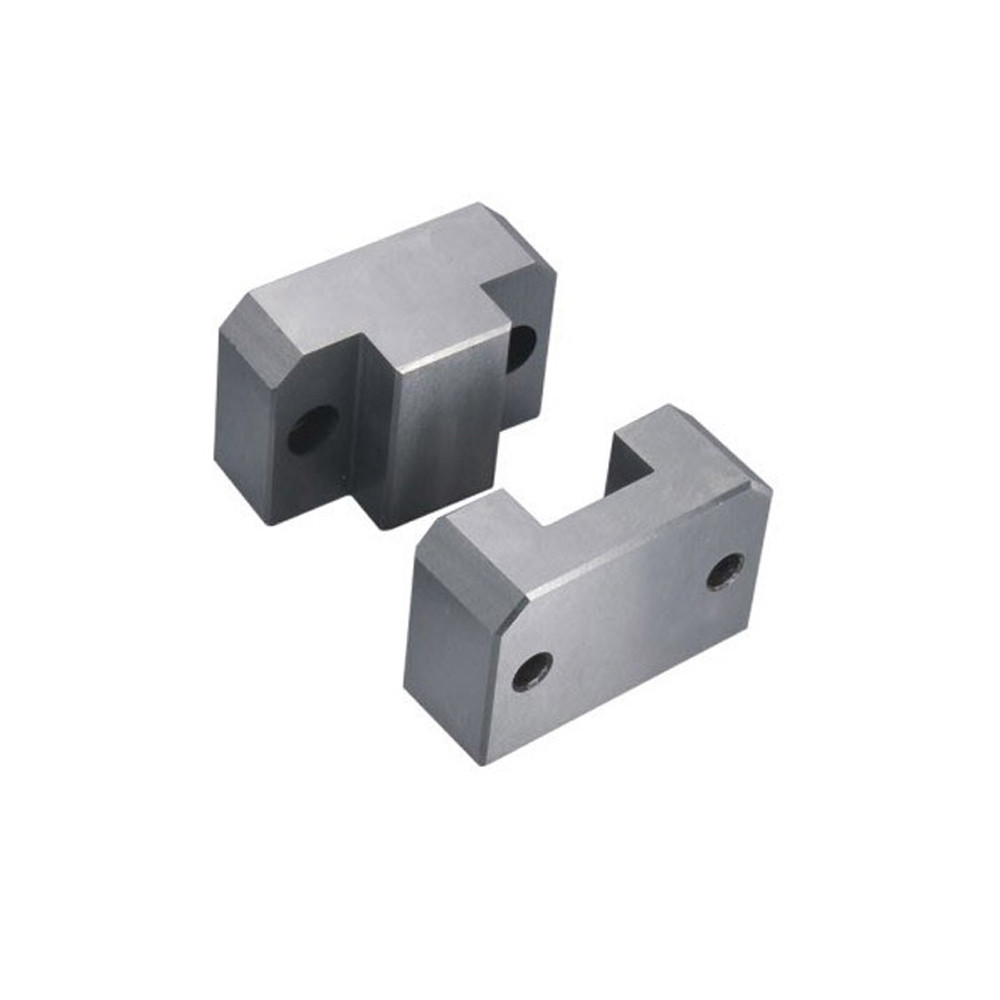

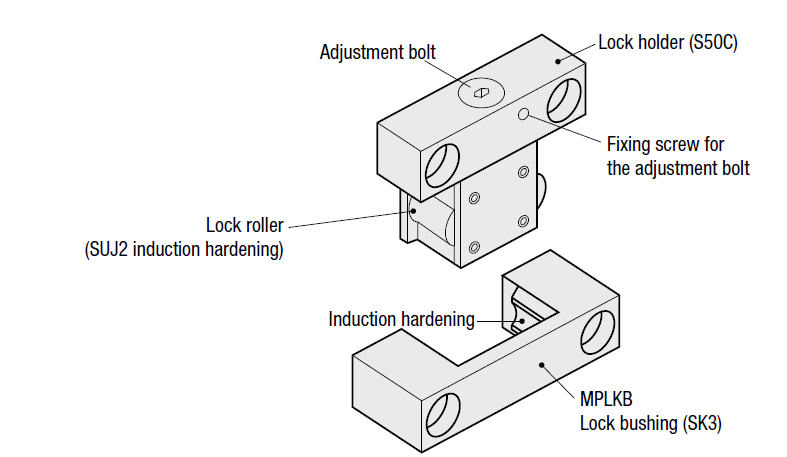

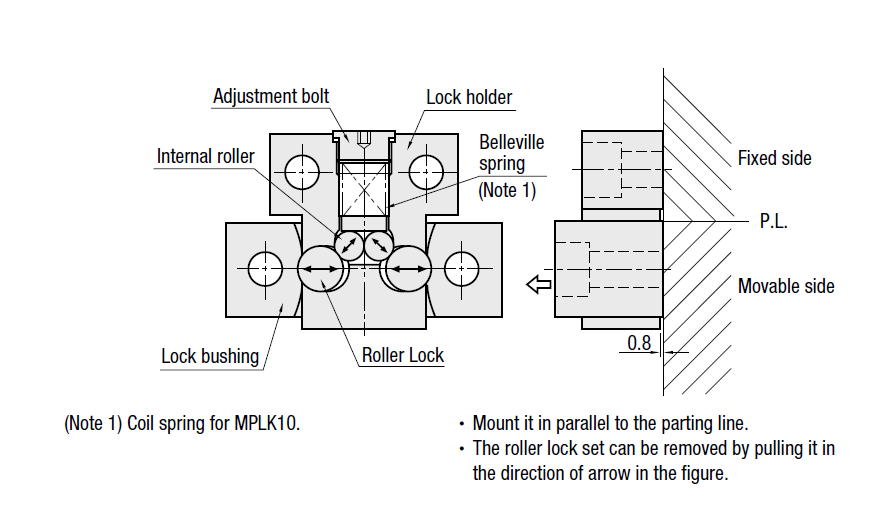

Ask For QuoteLatch lock is parts for controlling opening & closing of mold plates. It's composed of a belleville spring, internal rollers and lock roller.

Roller lock sets is one kind of locks. According to load and usage environment of mold, the locks could be divided into heat proof type(below 150°C, MPLKH) and standard type(below 80°C, MPLK). The standard type is black oxide, and trivalent chromate for heat proof type.

Rotating performance of roller wheel is good, and it could prevent uneven wear. Its life span is longer than Nylon parting locks, and no dust and impurities caused. Roller lock sets are widely used during designing &forming of mold. The lock bushing is with vertical symmetrical design, which allows a worn piece to be reused by reinstalling it in reverse.

Product name | Roller lock sets |

Standard | Japanese standard |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | S50C for lock holder, SK3 for lock bushing |

Hardness | - |

Mode | Factory & trade |

Feature

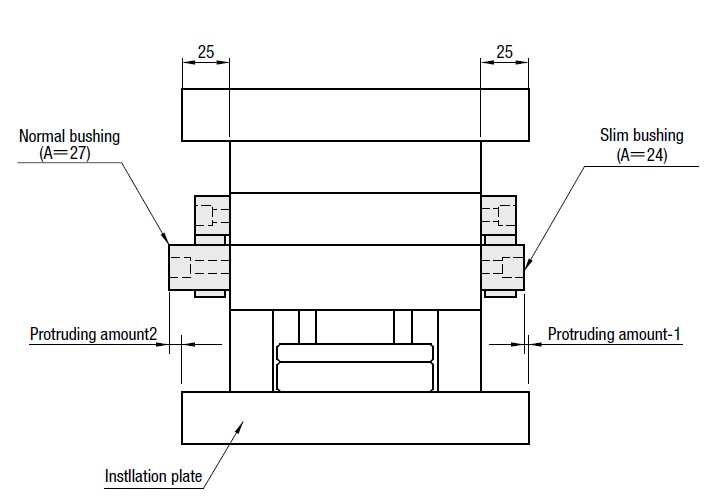

Struecture & usage

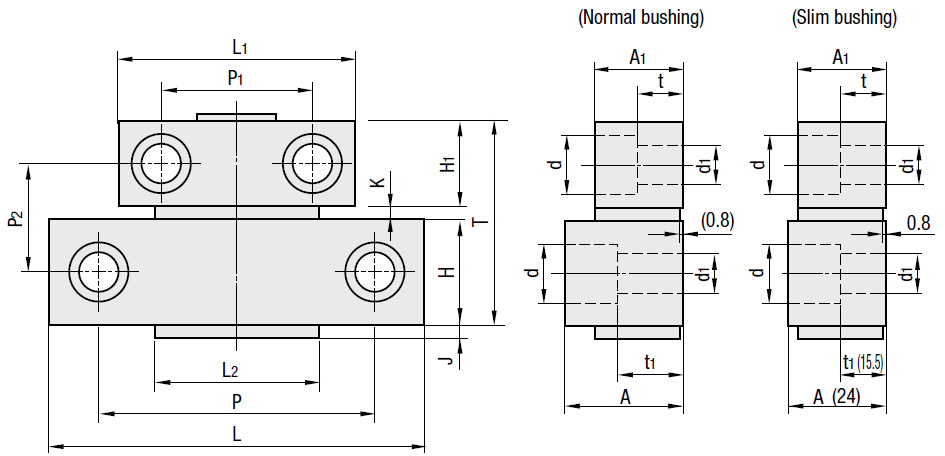

Standard Type · Heat Proof Standard Type (①+② sets)

| Part No. | Max. usable load( 2 sets under normal temp) | Size | |||||||||||||||||

| Type | No. | L | L1 | L2 | T | H | H1 | J | K | P | P1 | P2 | A | A1 | t | t1 | d | d1 | |

| (Normal bushing) MPLK | 10 | 981N(100kgf) | 48 | 36 | 25 | 42 | 22 | 18 | 2 | 2 | 36 | 24 | 22 | 24 | 16 | 9.5 | 18 | 11 | 6.5 |

| (Normal bushing) MPLK MPLKH | 20 | 1961N(200kgf) | 54 | 42 | 40 | 28 | 9 | 16 | |||||||||||

| 30 | 2942N(300kgf) | 65 | 46 | 35 | 48.5 | 25 | 20 | 3.5 | 3.5 | 50 | 31 | 26 | 27 | 19 | 9.5 | 17 | 7 | ||

| 60 | 5884N(600kgf) | 73 | 50 | 52 | 33 | 14 | 9 | ||||||||||||

| 80S | 7845N(800kgf) | 56.5 | 11.5 | 34 | |||||||||||||||

| 100 | 9807N(1000kgf) | 103 | 65 | 48 | 58 | 30 | 24 | 4 | 4 | 76 | 42 | 31 | 34 | 25 | 13 | 19 | 17 | 11 | |

| (Slim bushing) MPLKS MPLKHS | 30 | 2942N(300kgf) | 65 | 46 | 35 | 48.5 | 25 | 20 | 35 | 3.5 | 50 | 31 | 26 | 24 | 19 | 9.5 | 15.5 | 11 | 7 |

| 60 | 5884N(600kgf) | 73 | 50 | 52 | 33 | 14 | 9 | ||||||||||||

| 80S | 7845N(800kgf) | 56.5 | 11.5 | 34 | |||||||||||||||

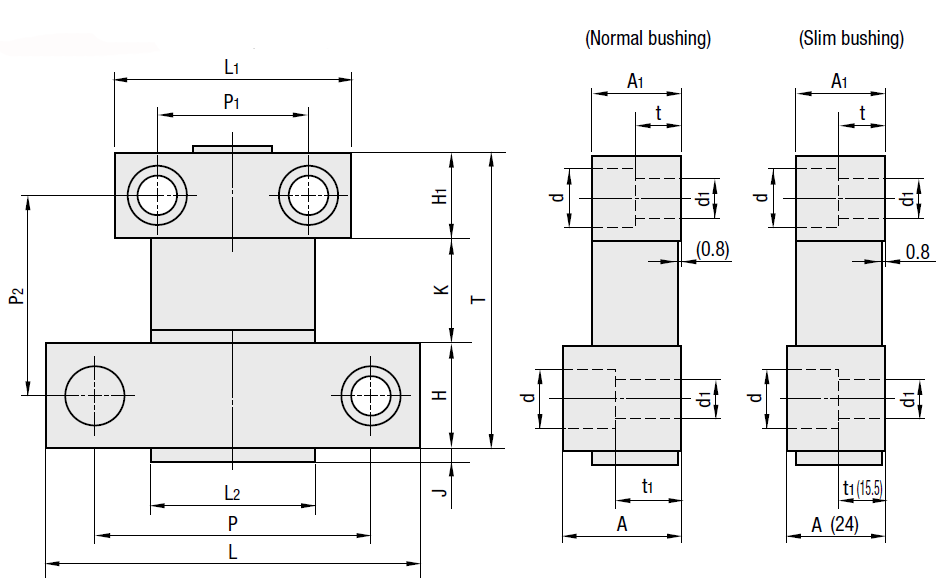

Long Type · Heat Proof Long Type (①+② sets)

Long Type · Heat Proof Long Type (①+② sets)

| Part No. | Max. usable load( 2 sets under normal temp) | Size | |||||||||||||||||

| Type | No. | L | L1 | L2 | T | H | H1 | J | K | P | P1 | P2 | A | A1 | t | t1 | d | d1 | |

| (Slim bushing) MPLK MPLKH | 60L | 5884N(600kgf) | 73 | 50 | 35 | 79.5 | 25 | 20 | 3.5 | 34.5 | 52 | 33 | 57 | 27 | 19 | 9.5 | 17 | 14 | 9 |

| 80 | 7845N(800kgf) | 87.5 | 42.5 | 65 | |||||||||||||||

| 100L | 981N(100kgf) | 103 | 65 | 48 | 89 | 30 | 24 | 4 | 35 | 76 | 42 | 62 | 34 | 25 | 13 | 19 | 17 | 11 | |

| (Normal bushing) MPLKS MPLKHS | 80 | 7845N(800kgf) | 73 | 50 | 35 | 87.5 | 25 | 20 | 3.5 | 42.5 | 52 | 33 | 65 | 24 | 19 | 9.5 | 15.5 | 14 | 9 |

Lock Bushing Component (② only) (Common with Heat Proof Type)

| Part No. | Application | ||||||

| Type | No. | ||||||

| (Normal bushing) MPLKB | 10 | For MPLK(H) 10 | |||||

| 20 | For MPLK(H) 20 | ||||||

| 30 |

For

MPLK(H) 30 For MPLK(H) S30 | ||||||

| 60 80 |

For

MPLK(H) 60·80·60L·80S For MPLK(H) S60·80·80S | ||||||

| 100 | For MPLK(H) 100·100L | ||||||

| Part No. | Application | |||

| Type | No. | |||

| (Normal bushing) MPLKSB | 30 |

For

MPLK(H) S30 For MPLK(H) 30 | ||

| 60 80 |

For

MPLK(H) 60·80·80S For MPLK(H) S60·80·80S | |||

| Type | Usage temperature | ||

| Normal bushing | Slim bushing | ||

| MPLK | MPLKS | Use under temperature 80°C | |

| MPLKH | MPLKHS | Use under temperature 150°C or lower(heat proof) | |

Comparison of Normal Bushing and Slim Bushing