Tie rod hydraulic cylinder

Description

Ask For Quote A tie rod hydraulic cylinder makes use of pressurised fluid bearing against a piston to generate a controlled force which could realize moving, lifting, holding and compressing.

According to how many directions the force applies in, hydraulic cylinder could be classified as single acting cylinders and double acting cylinders. Single acting cylinder is the simplest type of cylinder, it is moving in one direction only. Pressurised fluid enters through a port at one side of the cylinder, then it moves the piston to extend the rod. Under the action of external force, the piston would return to its previous position, and the hydraulic fluid would be forced back through the supply tubing to fluid reservoir. Double acting cylinder is the most commonly used cylinder, which has a port at both two sides of the cylinder, hydraulic fluid is supplied for the retraction and extension of the pistons. When an external force isn't available to retract piston, or high force is required in both directions of stroke, this type of tie rod hydraulic cylinder is a better choice in these situations.

Product name | Tie rod hydraulic cylinders |

Item No. | / |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | / |

Hardness | / |

Mode | Factory & trade |

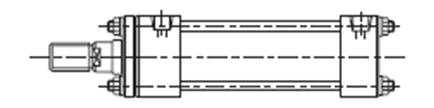

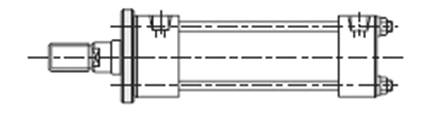

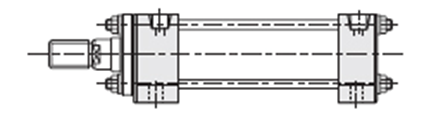

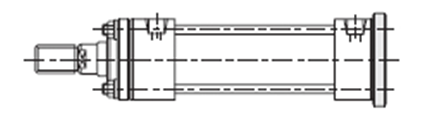

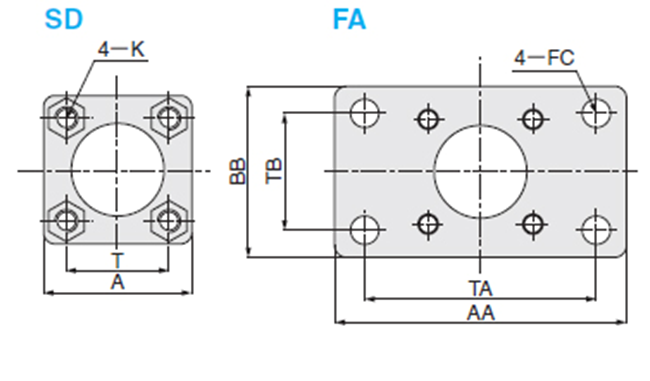

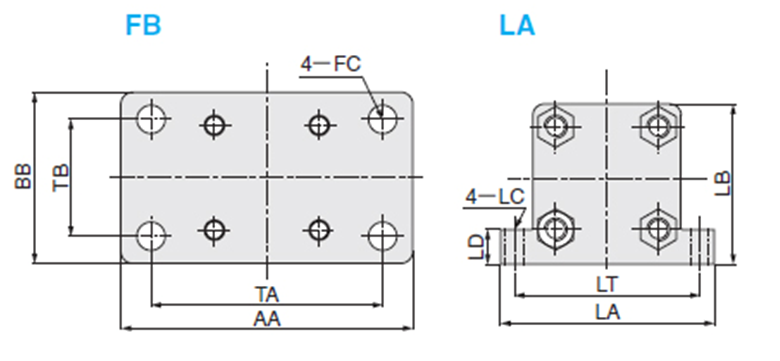

| Code | Name | Drawing | Code | Name | Drawing |

| SD | Basic |  | FA | Head-mounted |  |

| LA | Foot mount |  | FB | Cap-mounted |  |

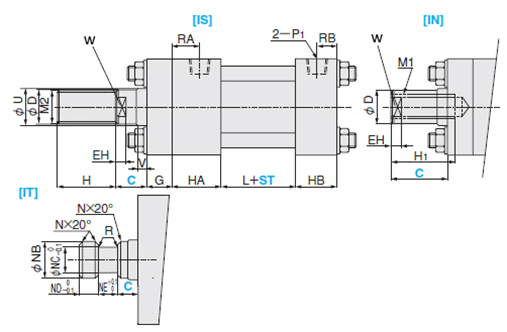

Cylinder dia. | D | L | W | G | HA | HB | RA | RB | P1(PT) | EH | H | H1 | M1 | M2 | NB | NC | ND | NE | R | N | U | V |

32 | 20 | 17 | 17 | 11 | 38 | 26 | 25 | 13 | 3/8 | 10 | 25 | 20 | M12 | M16 x 1.5 | 20 | 10 | 8 | 8 | 1 | 2 | 35 | 14 |

40 | 25 | 22 | 22 | 17 | 38 | 28 | 25 | 14 | 3/8 | 12 | 40 | 25 | M14 | M20 x 1.5 | 25 | 13 | 10 | 10 | 1 | 3 | 40 | 8 |

50 | 30 | 27 | 27 | 18 | 42 | 34 | 27 | 19 | 3/8 | 13 | 40 | 25 | M16 | M26 x 1.5 | 30 | 16 | 13 | 13 | 1 | 3 | 46 | 10 |

63 | 35 | 32 | 32 | 20 | 42 | 34 | 27 | 19 | 3/8 | 14 | 45 | 25 | M18 | M30 x 1.5 | 35 | 22 | 16 | 16 | 2 | 3 | 55 | 9 |

80 | 40 | 36 | 36 | 24 | 46 | 40 | 28 | 22 | 3/8 | 16 | 45 | 25 | M20 | M30 x 1.5 | 40 | 30 | 20 | 20 | 2 | 4 | 65 | 8 |

100 | 50 | 45 | 45 | 28 | 50 | 45 | 30 | 25 | 1/2 | 18 | 55 | 30 | M22 | M40 x 2.0 | 50 | 35 | 30 | 30 | 2 | 4 | 80 | 6 |

125 | 60 | 55 | 55 | 33 | 58 | 53 | 30 | 28 | 3/4 | 18 | 70 | 30 | M24 | M50 x 2.0 | 60 | 40 | 30 | 30 | 2 | 4 | 95 | 8 |

Cylinder dia. | SD | FA/FB | LA | ||||||||||

T | A | K | AA | BB | TA | TB | FC | LA | LT | LB | LD | LC | |

32 | 40 | 55 | M10 | 109 | 63 | 88 | 40 | 11 | 109 | 88 | 63 | 14 | 11 |

40 | 45 | 65 | M10 | 115 | 75 | 93 | 50 | 12 | 112 | 90 | 69 | 14 | 12 |

50 | 56 | 80 | M12 | 150 | 85 | 110 | 56 | 13 | 140 | 115 | 85 | 17 | 14 |

63 | 65 | 95 | M14 | 155 | 100 | 126 | 68 | 14 | 156 | 128 | 100 | 19 | 14 |

80 | 80 | 110 | M16 | 190 | 120 | 152 | 75 | 18 | 184 | 152 | 115 | 25 | 18 |

100 | 95 | 131 | M18 | 220 | 140 | 180 | 100 | 20 | 210 | 178 | 137 | 27 | 21 |

125 | 122 | 162 | M22 | 280 | 170 | 222 | 122 | 24 | 280 | 230 | 171 | 30 | 24 |

Pressure | Type | DD | ST( 1mm) | C(1mm) | Shape of piston rod | Heat resistance | Installation way |

M | |||||||

140kgf/cm2 | Compact hydraulic cylinder | 32 | 5~500 | 30~150 | IN | N(-5℃~80℃) | SD |

40 | |||||||

50 | |||||||

63 | 35~150 | ||||||

80 | |||||||

100 | 40~150 | ||||||

125 | 45~150 |