Latch locks for mold parts

Description

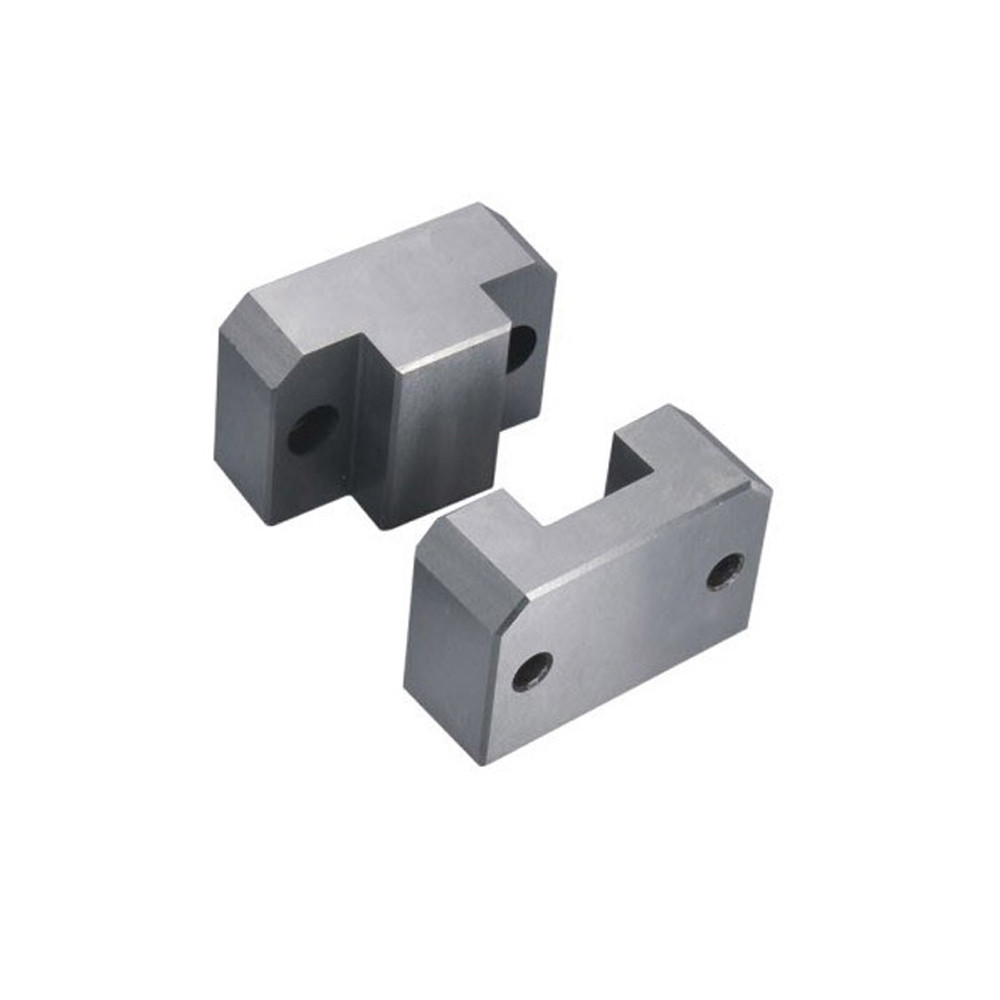

Ask For Quote Latch locks are used to control and float plates during the mould opening and closing sequence. The sets is made of high alloy steel after heat treatment, grinding, and high temperature resistance, with features of good flexibility, unique design and long service life.

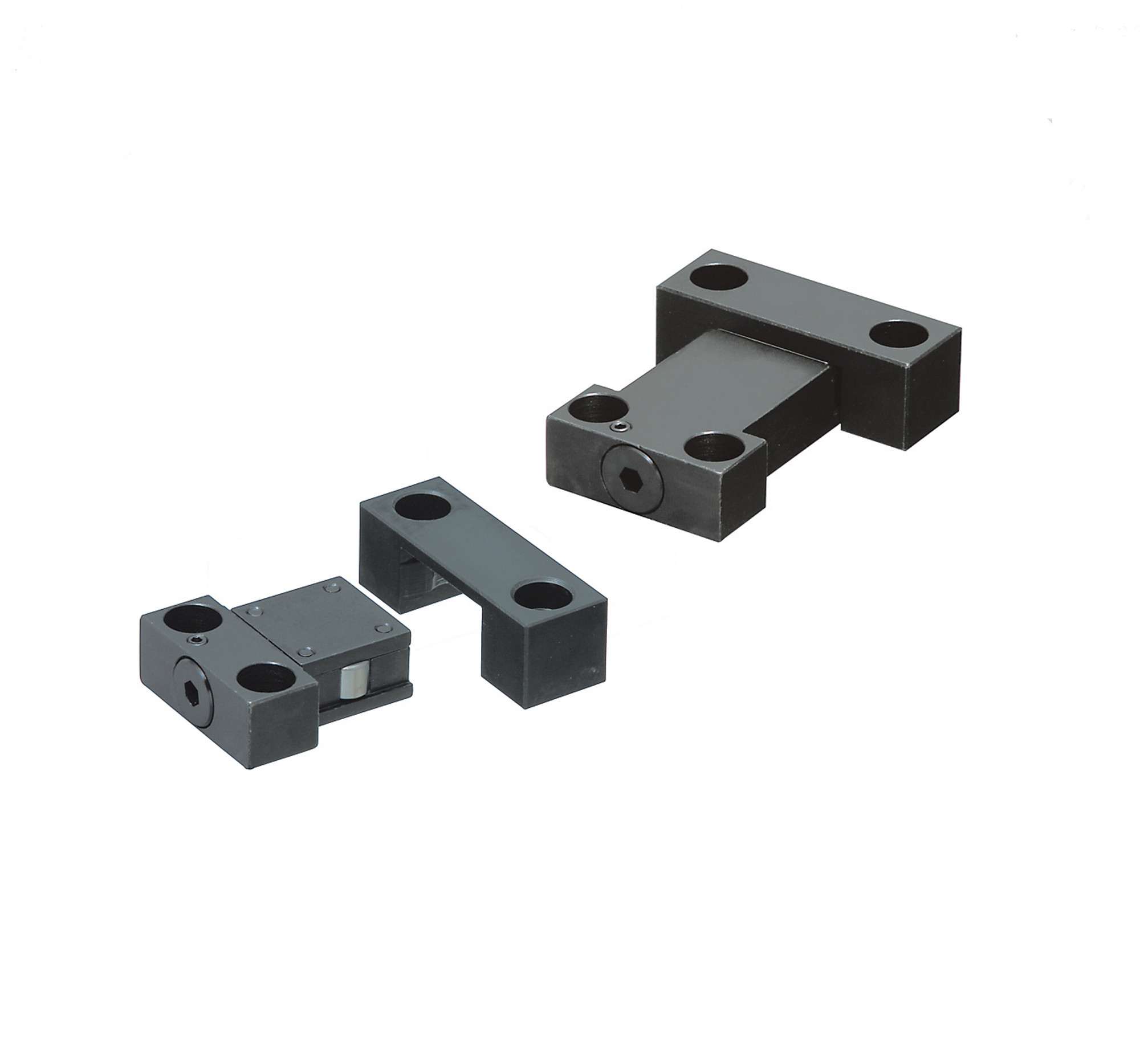

Screwing out two sides of screw caps, and then steel block at the middle could be separated from the whole body.

Please refer the installation instructions for side lock sets as below:

a) Latch locks for precision devices, symmetrical installation or might lead to a single set of clamping force imbalances, which would lead to clamping buckle fracture;

b) Mode-locking buckles tight fit between components, do not used in conjuction with other machined parts on their own;

c) Such as tooling maintenance changes, first remove clamping unit of a subsequent operation.

If have any unclear about our latch locks, please directly consult us. Look forward to your arrival all the time.

Product name | Latch locks for mold parts |

Item No. | / |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | S45C |

Hardness | / |

Mode | Factory & trade |

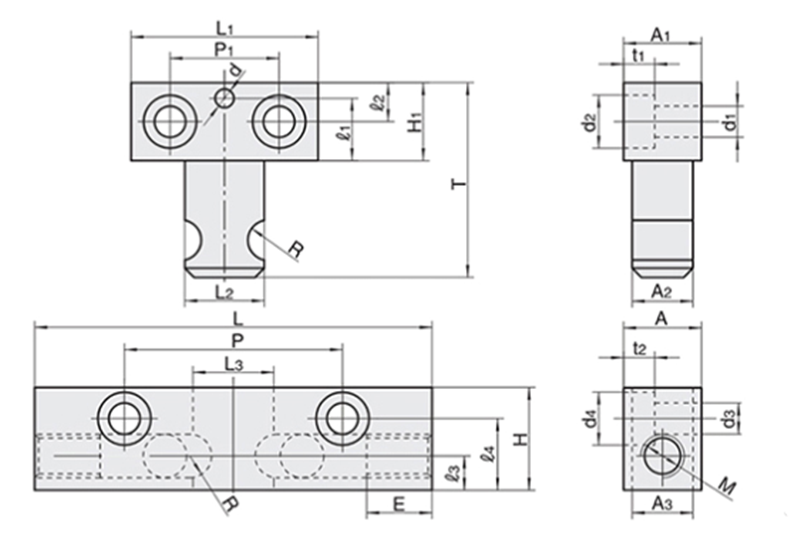

Model number | Max. working load(2 sets), reference value | L1 | P1 | l1 | l2 | T | H1 | L2 | t1 | A1 | d | d2 | d1 | A2 | R | L | P | L3 | l3 | l4 | H | E | t2 | A | d4 | d3 | A3 | M | |

Type | No. | ||||||||||||||||||||||||||||

E3 | 300 | 2942N(300kg) | 40 | 25 | 14 | 12 | 48 | 20 | 17.5 | 6.5 | 20.5 | 5 | 10.5 | 6.5 | 12 | R4.25 | 88 | 60 | 18 | 10 | 21 | 28 | 20 | 6.5 | 20.5 | 11 | 6.5 | 12.5 | M12x1.7 |

500 | 4902N(500kg) | 60 | 35 | 20 | 12.5 | 62.5 | 25 | 25.5 | 10 | 30 | 6 | 17 | 10 | 19.5 | R6.5 | 127.5 | 70 | 26 | 11 | 23 | 33 | 21 | 10 | 30 | 17 | 10 | 20 | M14x2.0 | |