Precision round head punch pin

Description

Ask For Quote Round punch pin is usually applied on stamping mould, and it's the commonest form of pin punch. Processed material would transform or segregate because of successive punching, after that, final product is formed.

With the advantage of high precision, tough hardness and special treatment, the cylindrical punch pins can be machined perfectly to fit your application and operate well.

At first, the specific raw material is drawing as necessary diameter by the drawbench, and then cut by appointed length. After a series of processes: heat treatment, abrasive machining, polishing and checking. The finished round pin punch comes out.

Different standard pin punches are available, and also provide customization service.

Product name | Round head punch pin |

Item No. | / |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | SKH-9, SKH-51, SKD11 and etc. |

Hardness | HRC 62-64 |

Mode | Factory & trade |

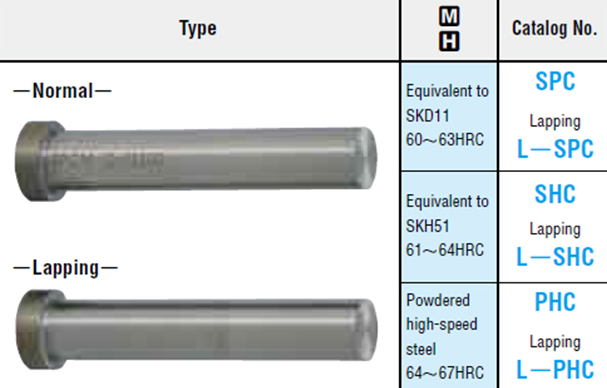

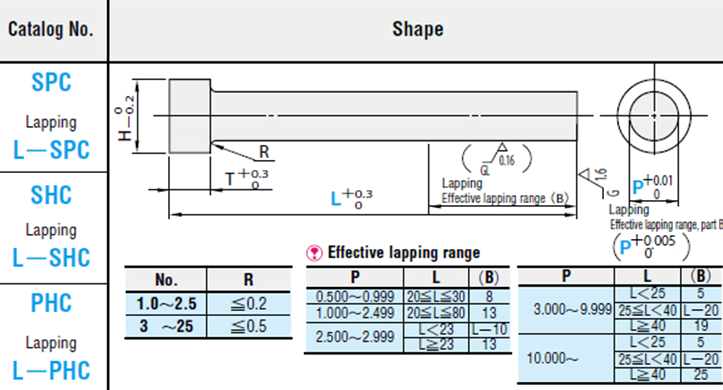

| Type | No. | L | 0.01mm increments(0.001mm increment for lapping) | H | T | ||||||

| min. P max. | |||||||||||

-Lapping- SHC L-SHC PHC L-PHC | 1.0 | 20 25 30 | 0.50~1.00 | 2.0 | 3 | ||||||

| 1.6 | 20 25 30 35 40 50 60 | 1.00~1.60 | 2.6 | ||||||||

| 2.0 | 20 25 30 35 40 50 60 | 1.60~2.00 | 3.0 | ||||||||

| 2.5 | 20 25 30 35 40 50 60 | 2.00~2.50 | 3.5 | ||||||||

-Lapping- SPC L-SPC SHC L-SHC PHC L-PHC | 3 | 40 50 60 70 80 | 2.00~3.00 | 5 | 5 | ||||||

| 4 | 40 50 60 70 80 | 3.00~4.00 | 7 | ||||||||

| 5 | 40 50 60 70 80 | 4.00~5.00 | 8 | ||||||||

| 6 | 40 50 60 70 80 | 5.00~6.00 | 9 | ||||||||

| 8 | 40 50 60 70 80 90 100 | 6.00~8.00 | 11 | ||||||||

| 10 | 40 50 60 70 80 90 100 | 8.00~10.00 | 13 | ||||||||

| 13 | 40 50 60 70 80 90 100 110 120 | 10.00~13.00 | 16 | ||||||||

| 16 | 40 50 60 70 80 90 100 110 120 | 13.00~16.00 | 19 | ||||||||

| 20 | 40 50 60 70 80 90 100 110 120 | 16.00~20.00 | 23 | ||||||||

| 25 | 40 50 60 70 80 90 100 110 120 | 20.00~25.00 | 28 | ||||||||