Precision stripper guide pin

Description

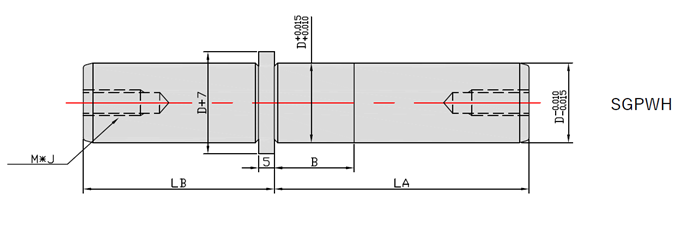

Ask For QuoteFix the guide pin at the position near cutting edge of the molds, in this structure, the rigidity of the pin could be improved several times. And it could also be processed with high precision blanking. Besides, the improvement of reliability for guide part could prolong the working life of the mould. In order to enhance durability of the product, the whole guide pin is processed with quenching.

Product name | Precision stripper guide pin |

Item No. | SGPWH, SGPWS |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | SUJ 2 |

Hardness | HRC 58 |

Mode | Factory & trade |

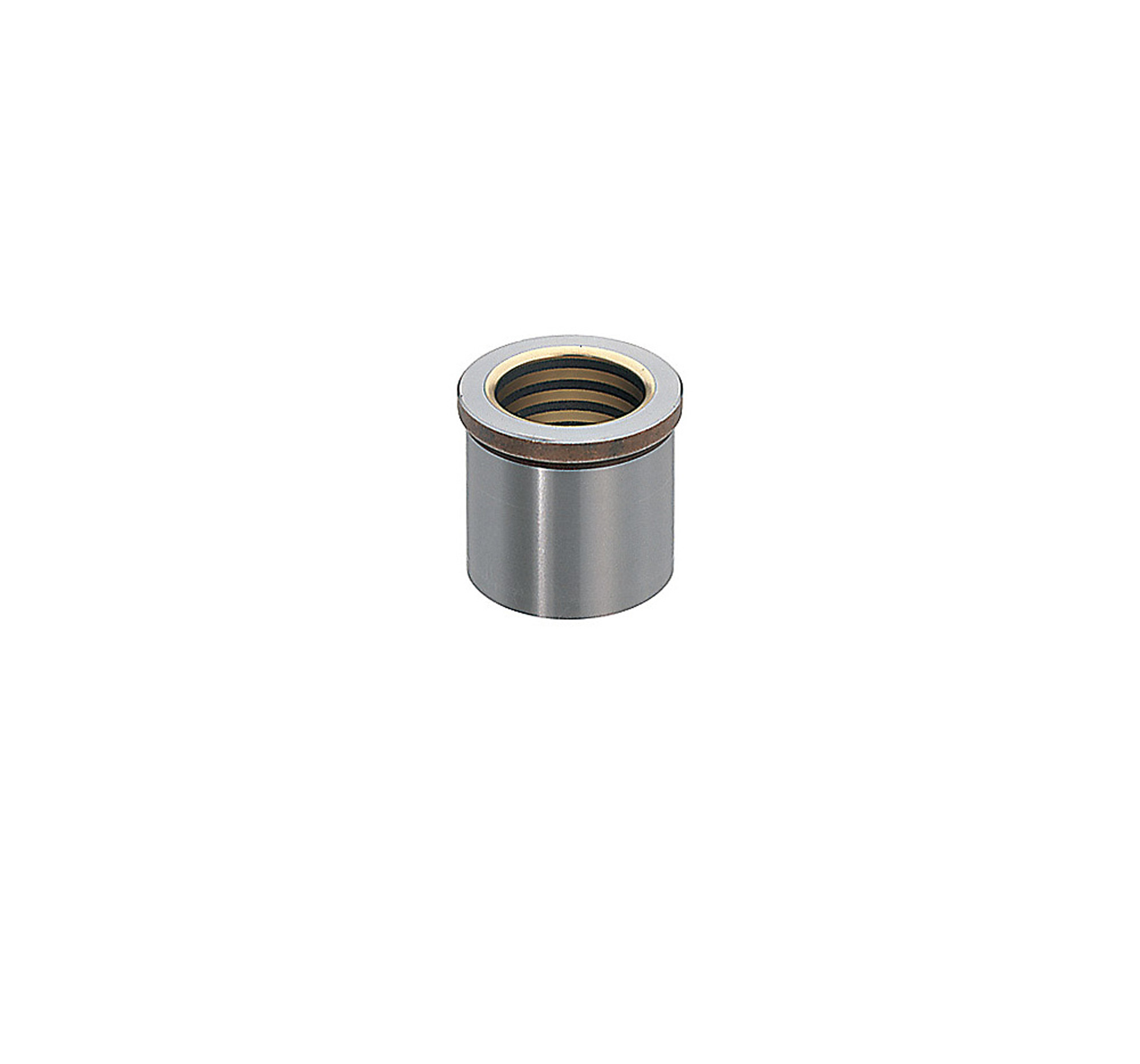

Flanged precision stripper guide pin, SGPWH

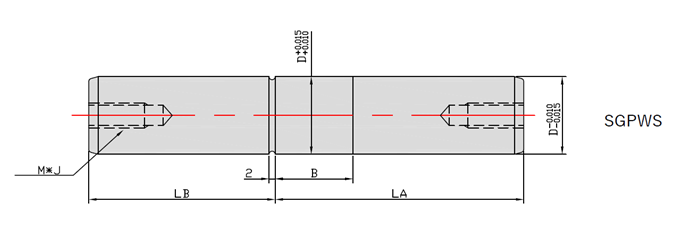

Straight precision stripper guide pin, SGPWS

M*J | Model No. | LA | LB | B | |

Type | D | ||||

M5*22 | SGPWH | 13 | 60 | 30~50 | 10~30 |

70 | 30~60 | ||||

80 | 40~60 | ||||

M6*25 |

| 16 | 70 | 30~60 | |

80 | 30~70 | ||||

90 | 40~80 | ||||

M8*25 | 20 | 80 | 40~70 | ||

90 | 40~70 | ||||

100 | 50~80 | ||||

25 | 90 | 50~70 | |||

100 | 50~80 | ||||

110 | 60~90 | ||||