Air ejector for injection mould

Description

Ask For Quote An Air poppet valve is used to assist with molded part ejection. The working principle of it is simple but effective. A small amount of gas is blown into the mold cavity (or off the core) at a desired location to assist with separating the molded part from the desired mold parting line feature. Air flow is timed to coincide with the ejection cycle, and this air flow opens the valve to break the vacuum and facilitate part ejection.

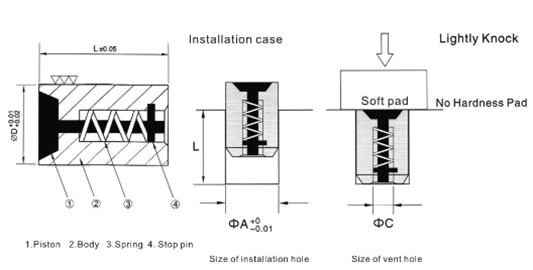

The structure of air ejector is obvious. It is composed of an outer casing, an ejector pin, a spring and a cylindrical dowel pin. Structure of all air ejector is similar, only have small differences on specification or standard.

Air poppet valve is an essential components for mold, and its effect is better than normal ejector pin in some certain situations. It could eliminate the troubles on design and manufacture of ejector pin, and solve the malfunction on ejection. In general, it is the breakthrough for mould and manufacture industries.

Product name | Air ejector for injection mold |

Item No. | Taiwan standard |

Manufacturer | MQ Mold |

Place of origin | Ningbo, China |

Material | SUJ 2 or SUS 420 |

Hardness | HRC 48-52 |

Mode | Factory & trade |

Type | Ext. dia. | Length | φA | φC | |||||||

12 | 15 | 20 | 25 | 30 | 35 | 45 | 55 | ||||

Air ejector | 5 | ● | 5 | 4 | |||||||

6 | ● | 6 | 4.5 | ||||||||

8 | ○ | ● | 8 | 4.5 | |||||||

10 | ○ | ○ | ● | 10 | 7 | ||||||

12 | ○ | ○ | ○ | ● | 12 | 7.7 | |||||

16 | ● | 16 | 10.3 | ||||||||

18 | ● | 18 | 12 | ||||||||

20 | ○ | ● | 20 | 12.9 | |||||||

25 | ○ | ● | 25 | 14.9 | |||||||

30 | ○ | ● | 30 | 18 | |||||||

Mark"●" represents standard size

Mark"○" represents optional size